Updated December 15th, 2024

3D PRINTING GUIDE FOR FDM

Home » Wiki Pages » 3D Printing Guide for FDM

Seattle Makers Guide to 3D Printing with FDM Technology

FDM: Fused Deposition Modeling. 3D printing objects by depositing filament materials (plastic, in this case) and fusing them together in a structure

To print FDM at Seattle Makers, we use software (called a slicer) named PrusaSlicer. There are many other slicers out there, but this works best with our printers. You can also set a profile for other printers that are not made by Prusa. Below is a guide to getting started, as well as reference materials for those who have completed certification.

Awesome reasons for using PrusaSlicer:

- You can test slicing (preparing prints) files at home.

- It’s free.

- Competitive feature-wise as compared to Simplify3D (a $100 software).

- It is optimized for use with our Prusa MK3 and MK4 Printers (same company).

First Time Setting up PrusaSlicer

PrusaSlicer Software

The latest stable release of PrusaSlicer can be always found on the Prusa website in the DRIVERS & APPS package, and it’s available for Windows, MacOS, and Linux. The package also includes test objects and printer drivers, but you can choose to install only PrusaSlicer.

- You can also download a standalone installer for your computer at PrusaSlicer introduction & download or at our GitHub.

- Download the appropriate file type for your computer

- Allocate Download Folder

If you’re new to PrusaSlicer, check out their awesome documentation for getting started. We also cover how to use it in our 3D Printer certification course.

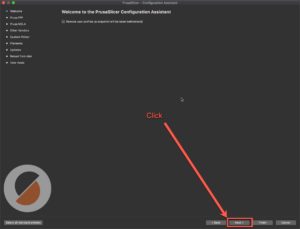

First Time Opening PrusaSlicer

Upon opening PrusaSlicer the first time, the Configuration assistant will automatically run.

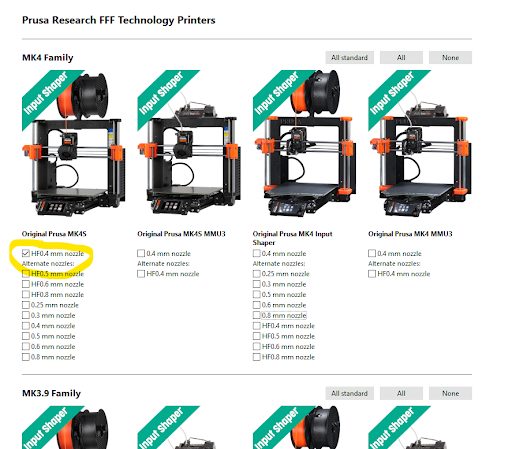

Then select Original Prusa MK4S H0.4 Nozzle

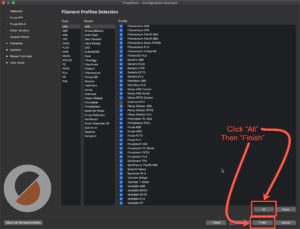

Click next until you see Filament Profiles Selection. Click All, then Finish.

Safety

- Get trained on the safe and efficient use of the printer before you use it.

- Do not touch the nozzle of the 3D printer with your hands. It is over 400°F (230C) when in use. Always assume that the nozzle is this hot. Use tweezers to clean extra filament from the nozzle.

- Remove the print bed and use gentle pressure or twisting to break parts loose when removing parts from a print bed. If this does not work, use the supplied plastic tools. This will keep the machines, your hands, and your print in good shape.

- When using the supplied print removal tools, start at one corner of the part and move slowly. Only apply the necessary amount of pressure. Most parts can be freed by getting the scraper just under the part, then twisting the scraper slightly to loosen the part.

- Always push away from yourself. Never put your hand or any part of your body in the potential path of the sharp object.

- Our 3D Printers are set up to be used with 1.75 mm diameter filament. They support printing with many types of filament (such as PLA, PETG, or TPU). If you are unsure about what settings and hardware need to be adjusted consult Staff or a Maketeer.

- Wait for the printer to completely stop before removing the print Stay an arm’s length away from the printer when in use

- If there is visible damage to the printer before, during or after use, inform staff/ volunteers. Do not start a print with visible damage.

- Always keep the area clean. Inform staff/ volunteers if filaments need to be re-ordered, or any tools/equipment is missing.

- Only use the cleaning equipment provided

- Direct any questions to the Maketeers on site or in the 3D-Printing-Team/3D-Printers Discord channels

How to Print!

The overview of Printing!

- Slice Your File

- Prepare The Printer

- Send G-Code to printer (Print!)

1. Slice Your File

Default Printer Profiles & Settings

These are the recommended starting settings for our printers. As part of the 3D printer certification, we show you step by step how to use PrusaSlicer if it is your first time.

Note: The rest of this section assumes you have already installed the profiles. Please see above for instructions on installing the printer profiles.

Jinja, Goddard, & Admiral – Prusa MK4S

Print Settings: 0.20mm STRUCTURAL

Filament: eSun PLA

Physical Printer: Original Prusa MK4S H0.4 Nozzle

Seattle Makers also recently added a Prusa XL printer with 2 print heads. Currently, this printer is only available for guided use, so coordinate with a Maketeer before beginning a project. Training on the XL printer will be available in the near future.

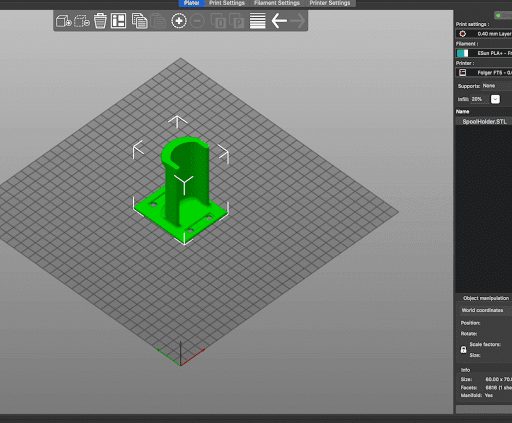

After choosing the preferred settings in PrusaSlicer:

- Import your model (STL, OBJ, AMF, 3MF, STEP)

- Arrange on build plate, OR press the Auto-arrange button (works 99% of the time)

- Make necessary changes to layer height or other settings.

- Slice your file

- Repeat as necessary

As always, Maketeers are here to help if you have questions about slicing.

Here’s a link to the documentation about PrusaSlicer.

2. Prepare The Printer

-

- If a completed print is left on the bed, please notify a Maketeer so we can remove it safely.

- Schedule & Pay

- Book time on the appropriate Google Calendar with your name and a description of your print. Make sure to reserve the printer for the expected duration of your print

- Pay in the store for your machine time.

- If the print fails and has to be stopped mid-print, let us know. You will only pay for the time the print was running and we will refund the difference.

- Choose Spring Steel Sheet Type

- Determine the correct Spring Steel Sheet to use based on Filament Type

- PLA = Smooth Sheet

- PETG, TPU (AKA FLEX) = Textured Sheet

- Steps to change Spring Steel Sheet (bed) – Please follow these instructions carefully, not following all steps will result in damage to the printer. This article goes into more detail about changing the steel sheets.

- Sheets are kept on the counter next to the printers

- Remove the current spring steel sheet

- Place new sheet on bed

- Determine the correct Spring Steel Sheet to use based on Filament Type

- Clean/Prepare the bed

- Ensure the bed is clear of debris and filament

- Wipe the bed down with KimTech Tissue Wipes and isopropyl alcohol

- Make sure not to touch the print bed between cleaning and printing. Natural skin oils can disrupt the print process and make it more prone to failure

- Ensure filament is loaded and is the correct color

- To Unload Filament

- Using the knob on the printer, navigate to Filament > Unload

- Wait for the printer to heat up.

- Press the knob to unload

- Clip off the very end of the filament to remove the blob.

- Hold free end of filament and attach to spool with a binder clip.

- Remove the spool carefully, and return to storage.

- To Load Filament

- Place roll of filament on printer

- Remove binder clip and hold onto free end of filament at all times.

- Clip off the very end of the filament is there is a blob.

- Insert filament into extruder head

- It will detect if there is filament.

- If filament was not detected, go to “Filament > Load”

- It will ask for filament type, choose what it says on the spool.

- Wait for the printer to heat up.

- Press the knob to load

- If filament is flowing correctly

- Filament extruding and with correct color? Yes

- To Unload Filament

- If color is not correct, press “Purge More” or “No”

-

-

- Remove extruded filament from nozzle.

-

3a. Transfer Files to Printer

The default method of transferring files to the printer is simply using a USB flash drive.

After you’ve finished slicing:

- Transfer the G-Code file directly to a flash drive, making sure you use the right physical medium for your intended printer.

- Alternatively, you may save the file to your Maker folder in the “public” drive on any computer in the makerspace. You can then use the 3D printing computer at the space to transfer your file.

Note: Each printer has its native flash card connected at all times. Please default to using these devices whenever possible

- Once the Flash Drive has been inserted into the printer, select “Print”

- Scroll to your file name and select it. Usually, the most recently saved file is listed first

- The printer will show a preview of this file. Verify that it matches what you are attempting to print

- Once verifying that you have the correct file, select print one final time.

Note: Most unsuccessful 3D prints will fail within the first couple printed layers. While Seattle Makers doesn’t require you to stay to monitor your entire print, we highly recommend that you watch the first few minutes of printing to make sure no errors occur.

3b. Send G-Code To Printer

Alternatively, we can transfer our files to the printers without the use of a flash drive or SD card. Using a raspberry pi and a program called PrusaLink, we now can send our G-Code directly from the slicer

Note: If you are having trouble with a Prusalink Interface, please ask a Maketeer.

There are two ways to send your print.

Directly from PrusaSlicer

This requires you to install an API Key in PrusaSlicer. Please contact William on Discord (@William K) to get the API key. This allows you to send files to PrusaLink and start your print without using the Flash Drive.

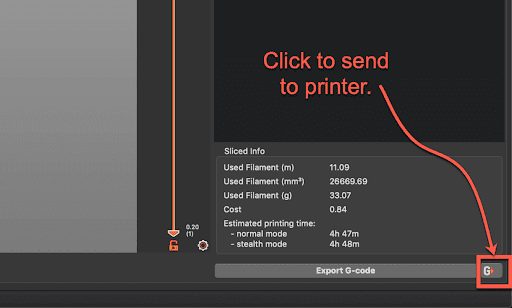

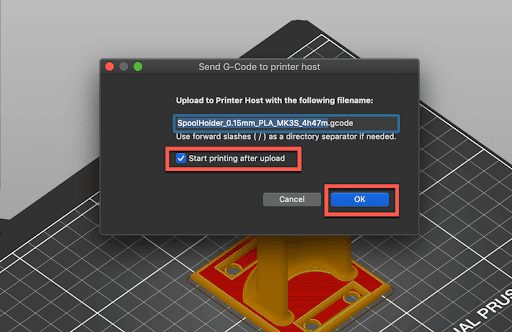

After you’ve finished slicing:

- Double check you have the correct printer.

- Click the tiny button in the lower right corner “G>.”

- If desired, check “Start Printing after upload.”

- Click “OK.”

Importing a 3D Model

Supported File Types

3MF – The preferred file format is also used to save Project files.

STL – Both binary and ASCII format is supported.

STEP – The STEP file is triangulated during import.

OBJ – Information such as material and texture is ignored during import.

Two Methods of Importing a Model into Prusa Slicer

Navigate to the Top Menu bar. Click on the Cube with the plus sign. Upload 3D model from computer library.

Navigate to File → Import → STL/ 3MF/STEP/OBJ/AMF…

Shortcut – Ctrl + I

Getting a 3D model

Generally speaking, a 3D model can be obtained through one of the following ways:

- Downloading a 3D model from the internet

- Creating your own models

- 3D scanning a real-world object

Online libraries and 3D hubs The easiest way to get started with 3D printing is to find 3D objects available on the internet for free. They usually come in .stl or .obj file formats. There’s a number of websites that offer a wide range of downloadable models – the best ones are listed below:

- Thangs is the fastest growing 3D community with over 15,244,288 available models to search, store, and collaborate. This website will search all of the other websites for 3D models. This is the best way to search for a particular thing but will be given a large scope to look through.

Printables

MakerWorld

- Thingiverse is the richest 3D archive on the internet. Currently, it offers more than 1.2 million models for free download – and the number keeps growing every day. It became a popular place for downloading, sharing and showcasing all sorts of 3D models.

- MyMiniFactory A popular repository with around 50,000 models by professional designers. All models are tested before publishing, so you can be sure you’re getting great quality STLs. The price of paid models is usually between 4 to 40 USD. Also, there is a great free repository available.

- YouMagine is a community website backed by Ultimaker. Models are divided into popular categories or collections curated by the site’s users. As of right now, the portal offers over 15,000 models for download.

- Pinshape A repository with more than 25,000 free 3D models and several thousands of paid models. An interesting difference between this site and the rest are various collections based around popular brands, such as Lego, IKEA or GoPro. According to the creators, Pinshape is a shop with high-quality 3D models. However, the website also offers many models for free. Designers can use this web to sell their own creations.

Prusa Community hub for all Prusa printer owners, and the only online library offering pre-sliced and print-ready G-codes! But it’s much more than just a library of STL or 3MF files! Join now and engage with the community in a variety of ways!

3D modeling

3D Modeling software Nowadays, you can pick from a wide range of various 3D modeling applications. There are simple and easy-to-learn (and often web-based) applications such as TinkerCad. You can try parametric modeling with OpenSCAD, or use a fully professional tool such as the popular Autodesk Fusion 360. All these applications enable you to create a model and export it as an STL file.

Tinkercad is a great and intuitive tool for beginners. It’s free, although a registration is required. You can find plenty of tutorials, guides and tips online. TinkerCad is built around the idea of a basic library with various shapes, which can be dragged into the main window and further modified. The application lacks advanced functions, however, it can import and edit an existing STL file. Tinkercad is available at

FreeCAD is an open-source parametric 3D modeler made primarily to design real-life objects of any size. Parametric modeling allows you to easily modify your design by going back into your model history and changing its parameters. www.tinkercad.com.

Autodesk Fusion 360 If you want to start designing more complex objects, or even various components that should fit together, then you need to select a more professional tool. Fusion 360 is a popular option. Users can work in both CAD (Computer-aided Design) and CAM (Computer-aided Manufacturing), strength analysis or visualizations. Fusion 360 offers not only parametric modeling, but even sculpting as well.

Blender is probably the best free 3D modeling tool available today. It’s developed under an open source license and it’s available for Windows, Mac and Linux. It may be a bit too complex for a beginner, chaotic even. However, it has found its way into the hearts of many users. Especially users with artistic ambitions, who don’t need precise parametric modeling, found Blender to be an amazing tool. Sculpting, texturing, animations… Blender is a Swiss army knife among 3D modeling applications.

OpenSCAD is an open-source project available for free from www.openscad.org. It takes a completely different approach to 3D modeling – everything is done by writing code. The user interface is divided into two parts. In the left section, the user defines 3D objects by ‘programming’ them, while in the right section, a 3D preview is displayed. The application works mostly with a couple of primitives (cube, cylinder, sphere,…) and basic boolean operations (join, cut, intersection). However, the program also allows for advanced scripting – you can use commonly known operators, such as if, while, for, logical operators and others. If you feel you are more of a programmer than an artist, you may give OpenSCAD a go.

You can also try the following applications:

Microsoft 3D Builder, Meshmixer Rhinoceros 3D, Autodesk Inventor, SolidWorks Autodesk, AutoCAD, and SketchUp.

3D Scanning

Photogrammetry (or SFM – Structure From Motion) is a process that estimates the three-dimensional coordinates of surface points using pictures of a single physical object taken from different angles. At least that’s the oversimplified one-line explanation. You take a bunch of pictures of the object from all possible directions, then you use these photos as an input for a specialized software. This software will look for features that are visible in multiple pictures and try to guess from which point the picture was taken. Knowing the camera positions and orientations, it creates a 3D point that corresponds to the 2D feature on the photo (basically a pixel). Ideally, you’d get a finished 3D mesh as an output. But often it might be better to process the reconstructed points into a mesh manually for much better results.

For more information on photogrammetry and the necessary software click here