Handwashing Station

Updated 05.11.20 at 20:20 PST

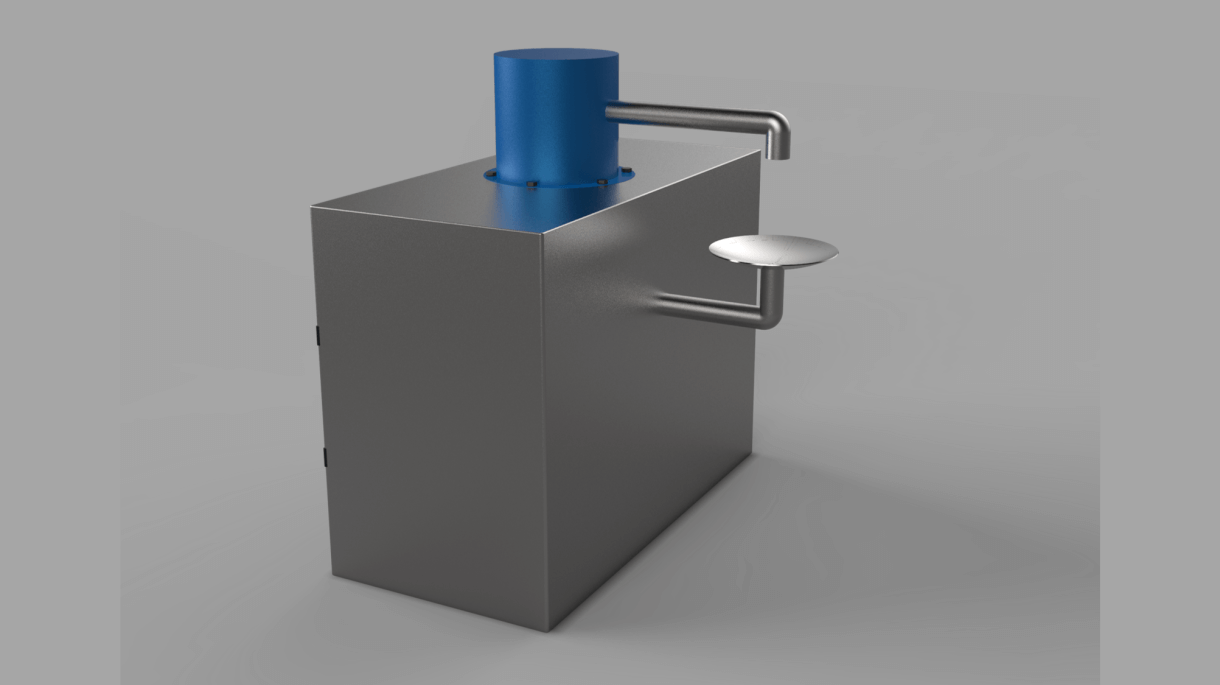

We are developing handwashing stations for homeless encampments and quarantine areas.

The City of Seattle reached out to us to develop a handwashing station for homeless encampments and quarantine areas. With many businesses and resources closed, the homeless community is left without a place to wash their hands. Without a solution, the virus will continue to circulate among our most vulnerable communities and the city as a whole.

The City of Seattle has deployed commercially available options (you’ve seen them at concerts and outdoor festivals). The plastic ones with the foot pumps). Unfortunately 4 out of 6 of these were soon stolen and/or destroyed.

The new model must be theft-proof, tamper-proof, and ADA compliant.

Prototype

Shell

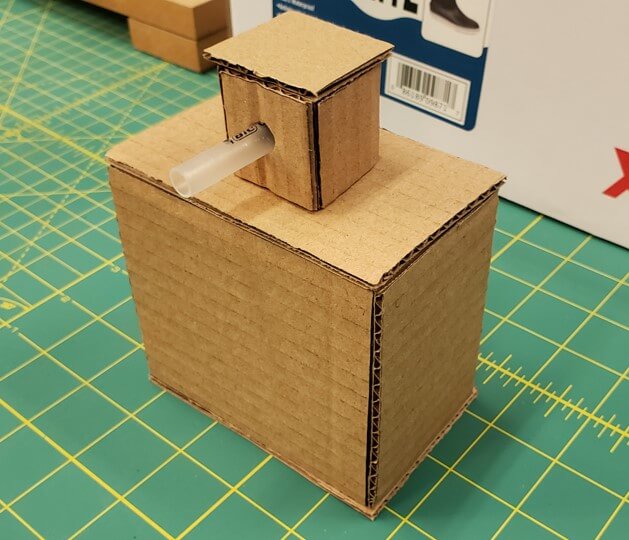

We put together a proposal for a metal-clad (read: heavy, tamper-proof) solution that can be safely placed in remote locations, and drained and refilled as necessary. It will also be designed to look like a giant hand soap pump, a visual aesthetic that will communicate its purpose. Here is an early cardboard rendition (without catchment sink):

Prototype of handwashing station made of cardboard

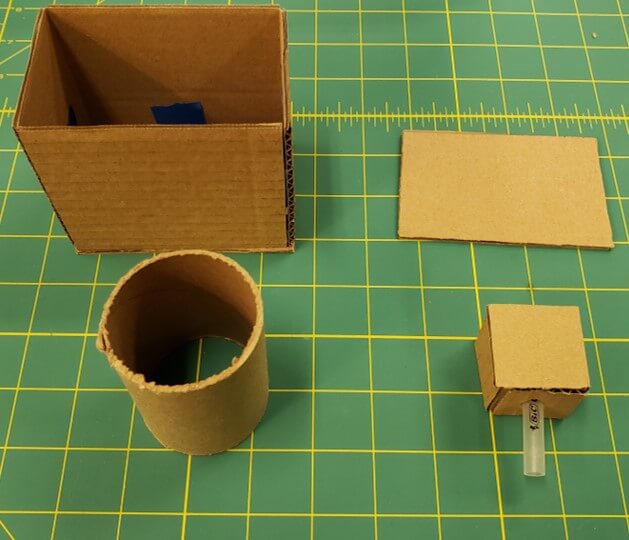

Component pieces of handwashing station prototype made of cardboard

The final version will be made of metal, but we’re starting with a wooden prototype, a lighter and lower cost proof-of-concept that will help us test the technology on-site and establish funding for dozens of these stations citywide.

Wooden prototype of the handwashing station, with metal plumbing components.

The prototype has a 55 gallon barrel for clean water, another barrel to store greywater (donated by Seattle Barrel Co.), a wooden shell, and metal plumbing and sink components.

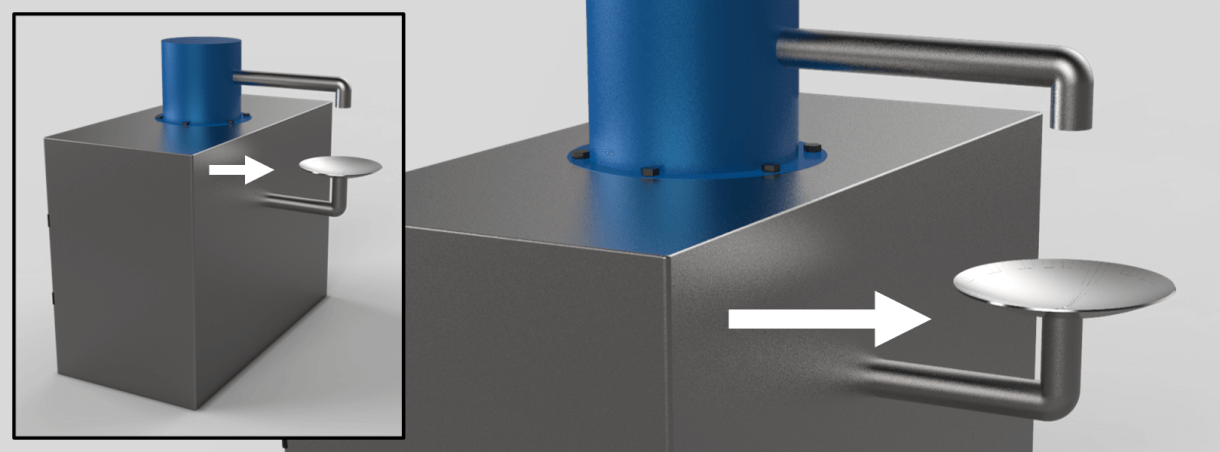

CAD drawing of the handwashing station with detail of metal sink portion.

The piping to support the sink.

Scott Kamp welds the sink to the support piping.

This wood prototype is battery powered with batteries swapped during refilling. The final metal model will solar charging.

Electronics

Maketeer Richard Albritton put together a proof of concept with an IR sensor to start the pump, and a timer to allow for 20 seconds of handwashing.

To facilitate 20 second handwashes and maximize water use, the electronics are programmed to turn the pump:

- On for 5 seconds to wet the hands

- Off for 25 seconds to get soap and wash

- On for 15 seconds to rinse

- Off for 10 seconds before the cycle can be restarted.

Final version

Metal Shell

We finalized the prototype design for mass production, and it has been approved by the ADA for accessibility.

Scott stands next to the first all-metal version that he welded together

Electronics

Richard’s design is programmed to limit water use for 20 seconds of handwashing, and features cost-saving and sanitary elements including:

- Water Level Reporting to know which locations need refilling in near real-time, communicated via LoRa (a Long Range communications networking protocol) using very little power, and reaching 2-3 km. This will save trips, time, and money, and ensure people will always have access to handwashing facilities.

- GPS capabilities, which will let the City know the exact location of of the station, in the unlikely event of it’s disappearance.

- Infrared or microwave sensor to turn on the water pump with no contact necessary.

Maketeer Jon Lenoff designed a custom PCB for the electronic components, which was fabricated at OSH Park in Portland, Oregon. With this PCB we can minimize costs and board footprint, reduce the number of potentially fragile wire connections, and increase the durability, all of which will help when we scale up production. Check out this cool stop-motion of the PCB assembly by Maketeer Jon Lenoff.

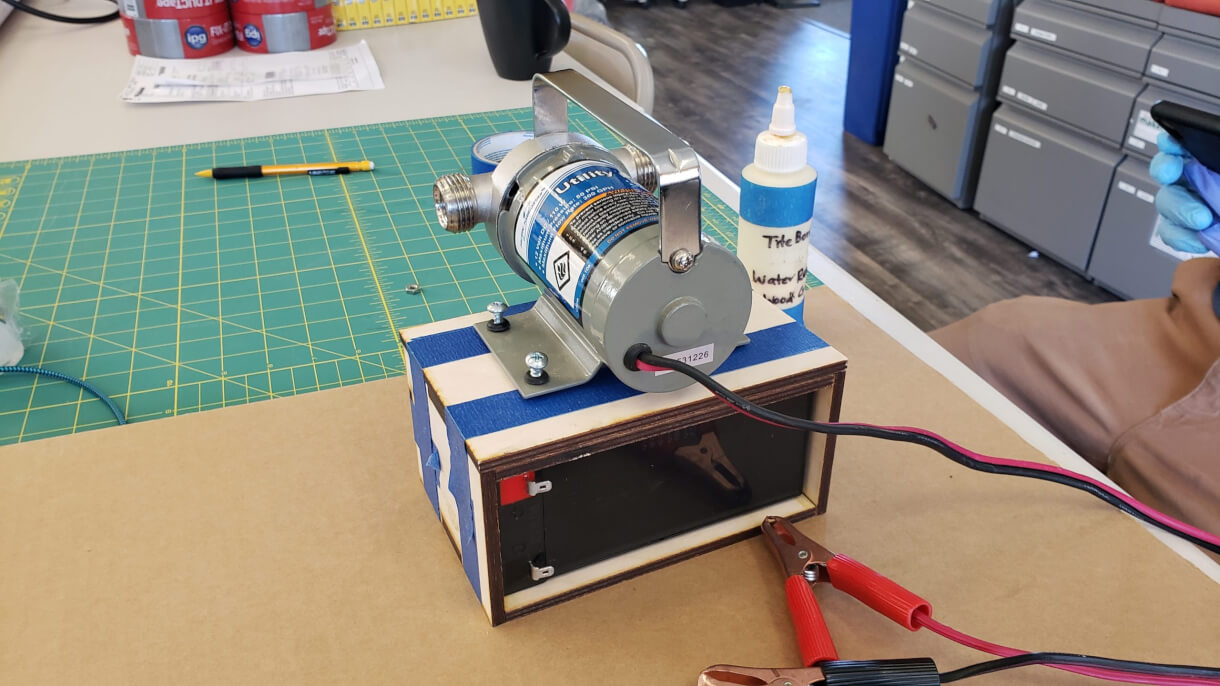

We’ve been working on the portable pump for draining the gray water barrel. Our testing shows it takes about 10 minutes to fill the barrel from the tap, and about 11 minutes to drain the graywater. The only other service needed is to swap out the battery. A handwashing station could be serviced with a simple pickup truck carrying two pumps, and two 55 gallon barrels, in about 15 minutes.

Battery-operated pump housed in wooden laser-cut box.

With a 55 second cycle time (5 seconds to wet, 25 to lather, 15 to rinse, and 10 seconds until next start), and a capacity for 160 washes, our station could be running nonstop for nearly 2.5 hours, with over 50 uses per hour.

Button

While our prototype uses a Staples™ Easy Button, we’ve acquired and are testing far beefier buttons that are waterproof and built to withstand abuse from hammers and feet (hey, at least that’s hands-free).

Our Team

Seattle Makers co-founder Jeremy Hanson is the lead coordinator and designer for the project, and co-founder of Seattle Makers.

Umar Khan, Seattle Makers maketeer, designed the CAD 3D versions of the design.

Chris Broughton, owner of Seattle Pedicab, researched and sourced materials, and gave feedback on the metalworking of the design.

Scott Kamp, of Cammeck Equipment, donated materials, expertise, and labor to produce the first metal version of our handwashing station.

Rusty Oliver, “Chief Executive Lunatic” of the Hazard Factory, provided additional feedback and design ideas. Rusty and his team (and amazing metal fabrication studio) are prepared to produce the units at scale, and deploy them quickly.

Richard Albritton, IOT expert and Seattle Makers maketeer, has developed a proof-of-concept, and worked with Adafruit to supply parts.

Jon Lenoff, Seattle Makers maketeer, designed a custom PCB for the electronic components, which is being fabricated at OSH Park in Portland, Oregon.

Trevor O’Brien, Seattle Makers maketter, developed a portable pump for draining the gray water barrel.

The City of Seattle has provided rainwater barrels from the Parks Department, provided all requirements for the stations and is searching for funding.

Seattle Barrel Co. donated two barrel to the prototype.

Fundraising

Funding through the City, State, or Federal level can be a long process. We’re looking to fund and build the first one, which with the help of Seattle’s amazing maker community, we estimate we can build each handwashing station for $7,250. This includes reliability upgrades to the electronics as well as a bladder system that will quadruple capacity. This is a third less than the commercial stations available from national outhouse companies.

Let’s Make It Happen

We’ve reached the $20,000 to build the prototype and are now asking for help reaching an additional $50,000 so we can build 6 handwashing stations at $7,250 each. Once we’ve finalized the parts and plans they will be made publicly available, and maker communities can implement this much needed solution worldwide. We’re all in this together, and our most vulnerable communities need a place to wash their hands and reduce the spread of the virus. Please help us by donating so we can all beat COVID faster.